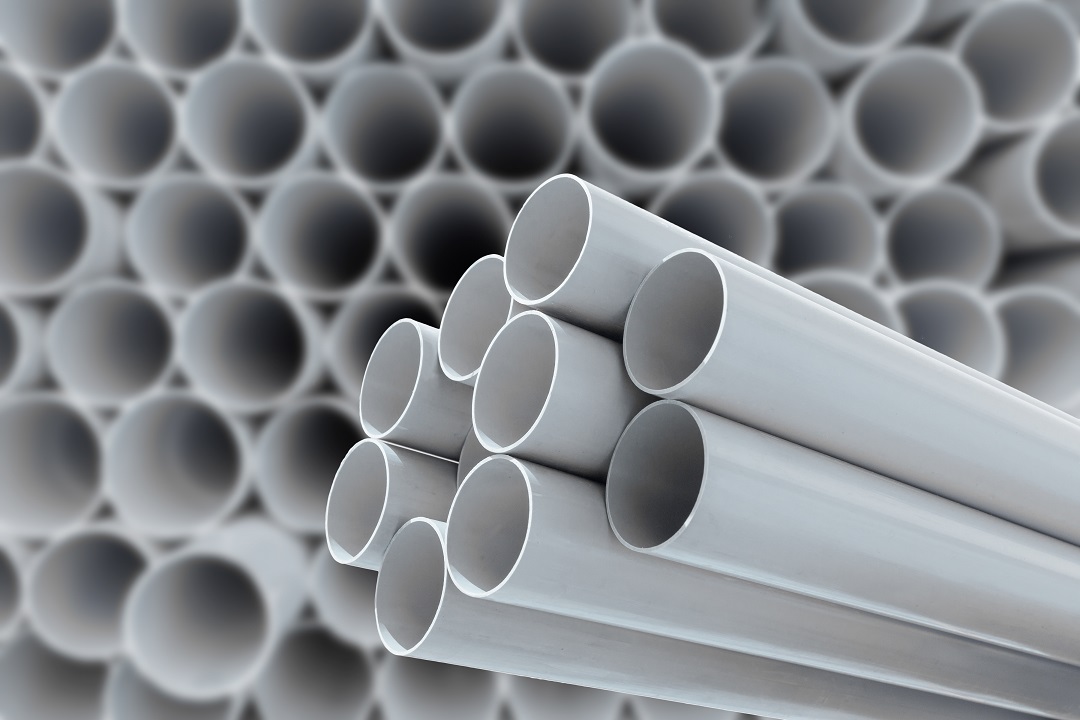

PVC Compounds (Polyvinyl Chloride Compounds) are a versatile and widely used polymer material known for their durability, chemical resistance, and adaptability. These compounds are engineered to offer a range of properties suited for various industrial, commercial, and consumer applications.

Key Features:

- Durability and Strength:

- High Tensile Strength: Offers robust mechanical properties and resistance to wear and impact.

- Long-Lasting Performance: Maintains structural integrity and functionality over extended periods, even in challenging environments.

- Chemical Resistance:

- Broad Chemical Resistance: Excellent resistance to acids, bases, salts, and a range of organic solvents.

- Suitable for Harsh Environments: Ideal for applications where exposure to chemicals is common.

- Thermal Stability:

- Temperature Range: Performs well across a wide temperature range, with a typical processing temperature around 160-200°C (320-392°F).

- Thermal Aging Resistance: Resists degradation over time under elevated temperatures.

- Ease of Processing:

- Versatile Processing: Easily processed using techniques such as extrusion, injection molding, and blow molding.

- Customizable: Can be formulated to meet specific processing and performance requirements.

- Moisture Resistance:

- Low Moisture Absorption: Resists water absorption, maintaining dimensional stability and mechanical properties in humid conditions.

- Waterproof Applications: Suitable for applications requiring resistance to moisture and water.

- Fire Retardancy:

- Flame Retardant Properties: Naturally resistant to ignition and burning, making it suitable for applications requiring fire safety compliance.

- Self-Extinguishing: Does not sustain combustion once the ignition source is removed.

- Versatile Applications:

- Construction: Pipes, fittings, window profiles, and flooring due to its strength, durability, and ease of installation.

- Medical: Tubing, containers, and medical devices where chemical resistance and safety are crucial.

- Packaging: Bottles, containers, and wraps that benefit from its durability and processability.

- Consumer Goods: Toys, household items, and electrical insulation for its flexibility and ease of processing.

- Customizable Formulations:

- Various Grades: Available in different formulations to meet specific needs, including rigid, flexible, and impact-resistant grades.

- Tailored Properties: Can be modified to enhance specific characteristics such as flexibility, color, or UV resistance.

Applications and Benefits:

- Construction Materials: Provides strength, weather resistance, and low maintenance for building applications.

- Medical Products: Ensures safety and chemical resistance for medical tubing and containers.

- Packaging Solutions: Offers durability and processability for various packaging needs.

- Consumer and Industrial Uses: Delivers a balance of performance and cost-effectiveness for a wide range of products.

PVC Compounds offer a reliable and adaptable solution for diverse applications, combining durability, chemical resistance, and processing ease to meet the requirements of various industries. Explore how PVC Compounds can enhance the performance and efficiency of your products.

Reviews

There are no reviews yet.